AnselAdams

Supporter

- 1,262

- 263

So when i finished the last post I mentioned that funding had been approved by the "Finance Minister" for improvements and upgrades. This week i started receiving those upgrades.

I want to provide acknowledgement of the assistance of advice already provided.

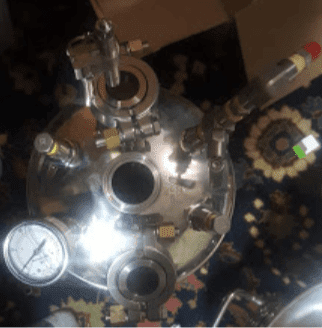

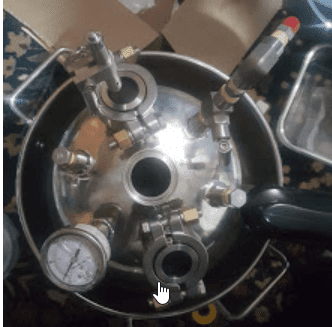

Frankie has grown up to a primary 8x10 spool; a 8" to 4" bowl reducer incl. splatter platter. The new 8" domed cap includes two 1.5" sight-glasses (one w/light). Two of the four 1/4" are plugged for later use. There is also a gas seat rated needle valve and -30/0/250 filled gauge.

dabarino... I heard you. My plan for the new and improved Frankie included far more capacity in the main tank than i will need under "normal" circumstances. I went with the domed features so as to allow for extra vacuum. The only hose i could find was a 10', my thought was go longer, not shorter; based on your suggestion. I was able to find a "Wancle SVC001 Sous Vide Cooker, Thermal Immersion Circulator" on Amazon along with a suitable warm water recovery pot. I am still waiting on my 8" HP clamps to arrive.

I will also be upgrading the Filter Stack and the Material Column sometime in the near future. But first comes vacation to Grand Teton/Yellowstone NP for some serious fall color photography opportunities.

I want to provide acknowledgement of the assistance of advice already provided.

When I got mine I said the same thing “I’m only ever going to run a qp at a time” hahaha that didn’t last long. I fill my 30# tank with 3 lbs of butane using a can tap tool and inject the entire tank into my extractor. I only fill it with what I need.. if you wanted to keep extra in there you could always use a refrigerant scale( you should have one anyway)

Frankie has grown up to a primary 8x10 spool; a 8" to 4" bowl reducer incl. splatter platter. The new 8" domed cap includes two 1.5" sight-glasses (one w/light). Two of the four 1/4" are plugged for later use. There is also a gas seat rated needle valve and -30/0/250 filled gauge.

... when sizing your collection pot to your column make sure you have 3 column volumes of space at only 80% capacity on your collection pot. You’ll notice they only size there’s for 2 column volumes.

Use only high pressure clamps

Get an immersion circulator for your hot water bath recovery

Get an 8’ solvent hose from your recovery tank to your extractor you’ll thank your self later

Oh and always build a bigger collection pot then you need because you can easily just add different column to it down the road it’s much easier then building another unit a few months down the road

dabarino... I heard you. My plan for the new and improved Frankie included far more capacity in the main tank than i will need under "normal" circumstances. I went with the domed features so as to allow for extra vacuum. The only hose i could find was a 10', my thought was go longer, not shorter; based on your suggestion. I was able to find a "Wancle SVC001 Sous Vide Cooker, Thermal Immersion Circulator" on Amazon along with a suitable warm water recovery pot. I am still waiting on my 8" HP clamps to arrive.

I will also be upgrading the Filter Stack and the Material Column sometime in the near future. But first comes vacation to Grand Teton/Yellowstone NP for some serious fall color photography opportunities.