B

Buddy Brain

- 11

- 3

Toaster - thank you for the suggestion on the Meanwell driver, I will check it out.

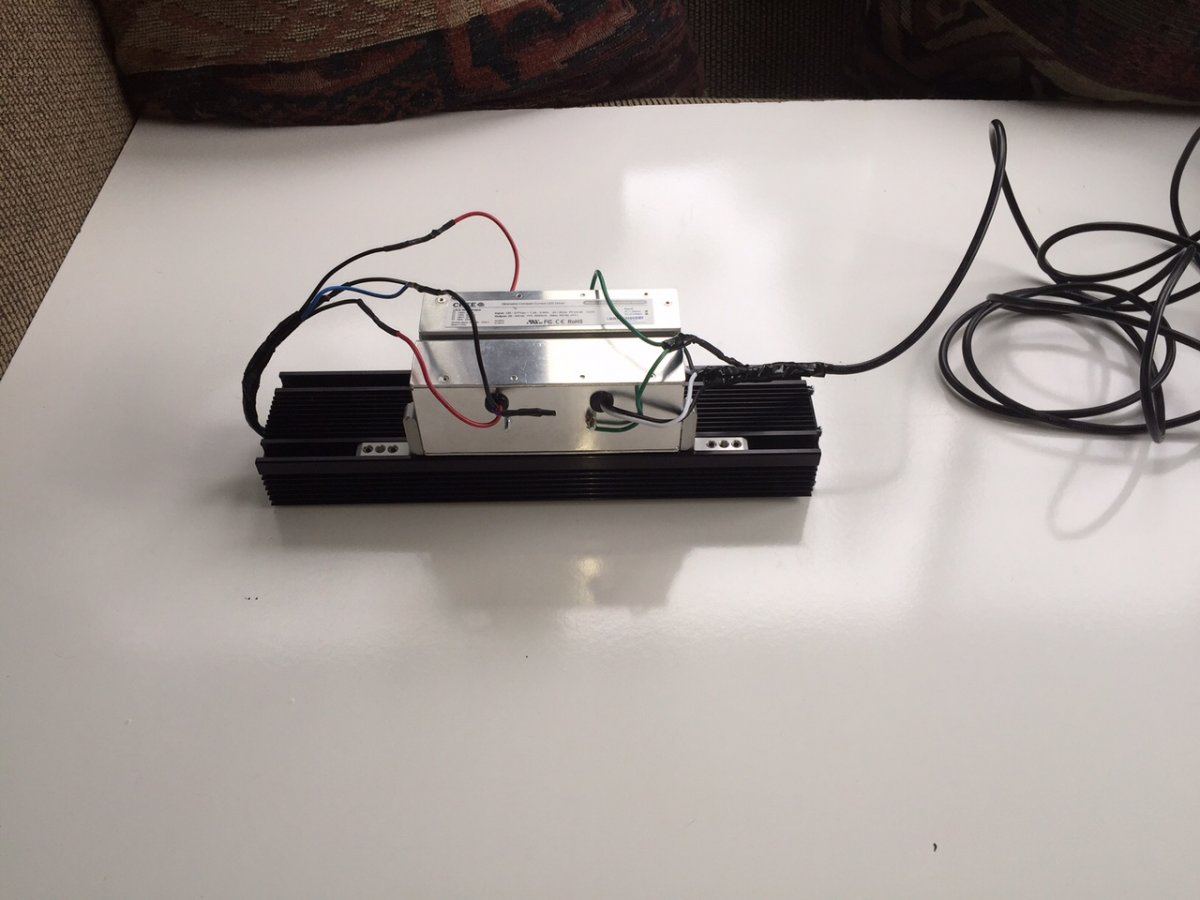

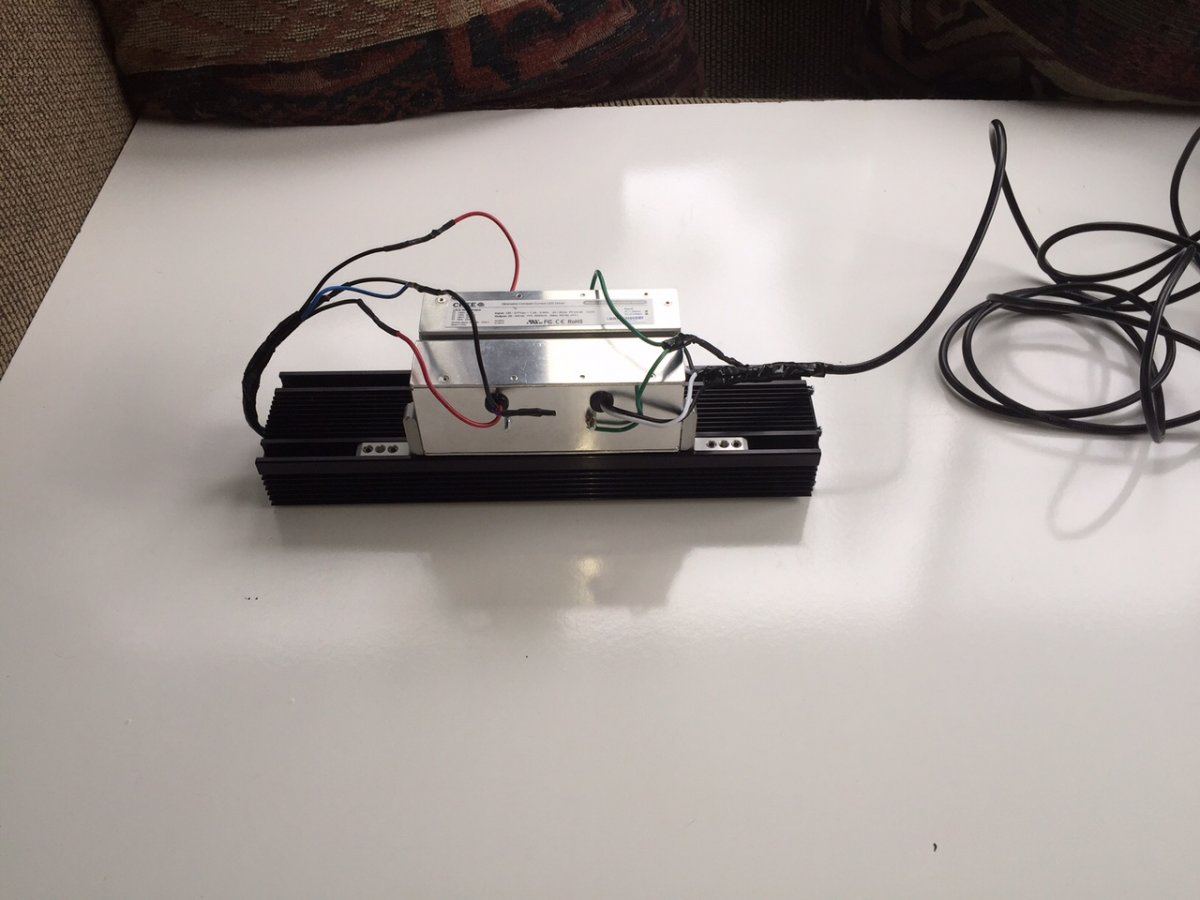

I re-posted the pictures as jpegs. The entire housing acts as a heat sink. I misspoke, it's actually a channel - not a pocket. The photo shows an extrusion with black anodize, but we have a lot of this stock that is simple silver (mill finish - no anodize). I am using a thermal adhesive paste, so the flat stock for the spacer is plenty flat enough as the paste fills in any gaps. I agree that it would be slightly preferable to have the channel shallow enough to not need the spacer plate, but as mentioned it was designed originally to be an LED light bar housing. The spacer is easy, just takes 5 minutes for the thermal adhesive to dry, I have the standoff pieces and can provide the spacer plate with the standoffs already attached. I could attach the spacer plate w/standoffs to the to the The other nice thing is that it has t-slots on the top, so (4) t-nuts can be used with eye-bolts to hang it, I have those too. The housing extrusion comes from the factory cut at 12' long, so I can have them cut to any length shorter than that. so if someone want a 48" or 60" light bar no problem

I re-posted the pictures as jpegs. The entire housing acts as a heat sink. I misspoke, it's actually a channel - not a pocket. The photo shows an extrusion with black anodize, but we have a lot of this stock that is simple silver (mill finish - no anodize). I am using a thermal adhesive paste, so the flat stock for the spacer is plenty flat enough as the paste fills in any gaps. I agree that it would be slightly preferable to have the channel shallow enough to not need the spacer plate, but as mentioned it was designed originally to be an LED light bar housing. The spacer is easy, just takes 5 minutes for the thermal adhesive to dry, I have the standoff pieces and can provide the spacer plate with the standoffs already attached. I could attach the spacer plate w/standoffs to the to the The other nice thing is that it has t-slots on the top, so (4) t-nuts can be used with eye-bolts to hang it, I have those too. The housing extrusion comes from the factory cut at 12' long, so I can have them cut to any length shorter than that. so if someone want a 48" or 60" light bar no problem