Pondracer

- 388

- 93

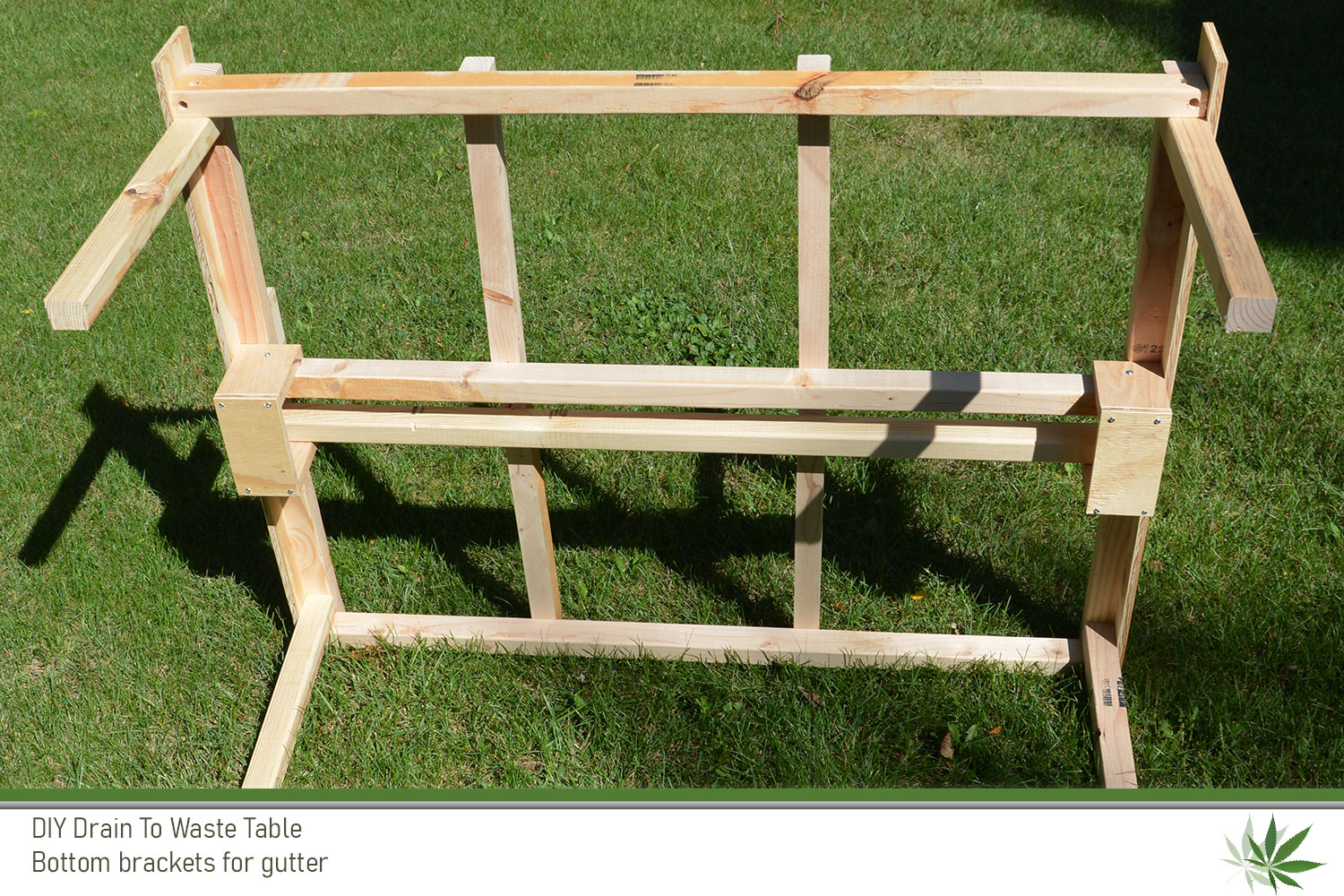

I was tired of pooling waste water under my plants and having to manually drain my waste sump. I wanted some type of nicer table that would allow me to clean and disinfect everything after each run. I love the Dutch tables but I wasn't going to spend a grand on a table and a lot of them just seemed to give up too much height. I ended up building 3 tables with an end cost of around $100 per table. The pictures here show the table that is in my veg area and has more height and has not been plumbed for irrigation.

The 1/2 inch pipe you see in the center is a dummy pipe that carries no water. Its only function is to keep the dishwasher trays from sliding down into each other. It only maintains that spacing so the runoff drips down into the main drainage gutter. The main drainage gutter is a length of Schedule 40 4" PVC pipe that I split down the middle on the bandsaw. The reason for the spacer between the trays is so that they do not have to be attached to the main table in any way. Removing them for cleaning is just a matter of picking them up, going to the sink and bringing them back. The main main drainage gutter is similar. Its held in place with a wood cradle and removal is just sliding it out. The pitch for all these areas is a basic 1/8 to 1/4 inch per foot that is built into the structure so the actual table can just be level.

The end pieces are screwed together and then the main frame is attached. For the gravel floor I wasn't concerned with being too precise. For the two that go in the tent the leveling feet take care of keeping it from rocking. I made the frame out of 2x4 studs that I ripped in half on the table saw. None of this is fine furniture. I wanted something durable enough to last and a design that would fit into my 5x9 tent. Two of these fit nicely with a 1 foot gap on the back for irrigation and other neccessary things and a 2 foot gap in the middle so I can step between the tables for maintenance. I went ahead and used a waterproof glue (Titebond III) along with face frame screws to secure the structure. The glue just adds another bit of rigidity and strength.

Two coats of cheap exterior paint helps protect it in a damp environment. I could have figured out how to do it with PVC but this is faster and I understand how to use wood. The paint keeps it mostly protected, I can wipe it down when its dirty and the white shows any area that might give me problems. The two tables that will end up in my tent after this run were built to use a 12" high storage box as a sump with a float switch and submersible pump. The same for the veg area but it sits slightly higher.

Bill of Material

3 8' 2x4

1 4x8 sheet 1/2" exterior ply

1 10 feet 4" pipe

1 10 feet 1/2" pipe

4" end cap

4 1/2" T

6 1/2" end cap

White exterior paint

4 each Camco Dishwasher trays

$17 each

https://www.amazon.com/dp/B0793DZHFM/ref=cm_sw_em_r_mt_dp_7bTzFb69YBAVF

The 1/2 inch pipe you see in the center is a dummy pipe that carries no water. Its only function is to keep the dishwasher trays from sliding down into each other. It only maintains that spacing so the runoff drips down into the main drainage gutter. The main drainage gutter is a length of Schedule 40 4" PVC pipe that I split down the middle on the bandsaw. The reason for the spacer between the trays is so that they do not have to be attached to the main table in any way. Removing them for cleaning is just a matter of picking them up, going to the sink and bringing them back. The main main drainage gutter is similar. Its held in place with a wood cradle and removal is just sliding it out. The pitch for all these areas is a basic 1/8 to 1/4 inch per foot that is built into the structure so the actual table can just be level.

The end pieces are screwed together and then the main frame is attached. For the gravel floor I wasn't concerned with being too precise. For the two that go in the tent the leveling feet take care of keeping it from rocking. I made the frame out of 2x4 studs that I ripped in half on the table saw. None of this is fine furniture. I wanted something durable enough to last and a design that would fit into my 5x9 tent. Two of these fit nicely with a 1 foot gap on the back for irrigation and other neccessary things and a 2 foot gap in the middle so I can step between the tables for maintenance. I went ahead and used a waterproof glue (Titebond III) along with face frame screws to secure the structure. The glue just adds another bit of rigidity and strength.

Two coats of cheap exterior paint helps protect it in a damp environment. I could have figured out how to do it with PVC but this is faster and I understand how to use wood. The paint keeps it mostly protected, I can wipe it down when its dirty and the white shows any area that might give me problems. The two tables that will end up in my tent after this run were built to use a 12" high storage box as a sump with a float switch and submersible pump. The same for the veg area but it sits slightly higher.

Bill of Material

3 8' 2x4

1 4x8 sheet 1/2" exterior ply

1 10 feet 4" pipe

1 10 feet 1/2" pipe

4" end cap

4 1/2" T

6 1/2" end cap

White exterior paint

4 each Camco Dishwasher trays

$17 each

https://www.amazon.com/dp/B0793DZHFM/ref=cm_sw_em_r_mt_dp_7bTzFb69YBAVF