DGP

- 1,214

- 263

First off I decided to post here in Hydro because the UC forum was under "Tree Growing" and I don't grow trees right now just run straight up hydro trying to turn a cycle every 3 months or so.

I cant afford a $4,000 UC system so I set out to design one of my own. I tried 2 prototypes and admit that they were not the best solution but I learned a lot in the process. I thought I would share the experience in case someone else wanted to try UC without selling an organ or giving up a left nut and an arm.

My first system used Uni-seals (AKA Uni-Leaks) and they were nearly impossible to assemble and in the end just leaked. I personally think they are garbage but that's just my opinion.

Second prototype worked but had some weaknesses. I used conduit bulkheads and like I said they worked but the potential for leaks is still there. It is cheaper than my final design but I moved on.

I spent about $500 on my testing and final design due to the failed parts but the final design can be reproduced for about $300 or less depending on what sort of materials you may be able to scrounge around your grow like pumps, hose, hardware etc. So even if I spent $500 it still yielded me a system that works wonderfully and didn't cost $4K.

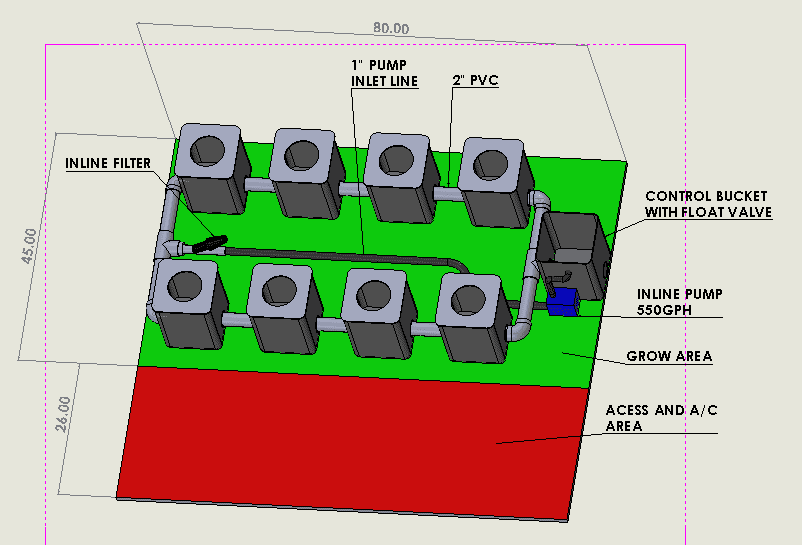

The basic system uses square, black food grade buckets, aquarium 2" bulkhead fittings and common PVC 2" pipe and fittings from the hardware or big box home improvement store. The only thing I had to order special was the bulkheads and buckets.

I will post a bill of materials with costs and sources along with a design diagram.

My plants have been in the system only a few weeks but are thriving and I can't believe the quality of the root system already. I have large root bundles as well as huge (pinky size) diameter main roots. The stems on my plants are bigger in diameter already compared to where my last grow finished.

All in all I am very happy with the system. Will be adding more detail shortly along with some photos.

I cant afford a $4,000 UC system so I set out to design one of my own. I tried 2 prototypes and admit that they were not the best solution but I learned a lot in the process. I thought I would share the experience in case someone else wanted to try UC without selling an organ or giving up a left nut and an arm.

My first system used Uni-seals (AKA Uni-Leaks) and they were nearly impossible to assemble and in the end just leaked. I personally think they are garbage but that's just my opinion.

Second prototype worked but had some weaknesses. I used conduit bulkheads and like I said they worked but the potential for leaks is still there. It is cheaper than my final design but I moved on.

I spent about $500 on my testing and final design due to the failed parts but the final design can be reproduced for about $300 or less depending on what sort of materials you may be able to scrounge around your grow like pumps, hose, hardware etc. So even if I spent $500 it still yielded me a system that works wonderfully and didn't cost $4K.

The basic system uses square, black food grade buckets, aquarium 2" bulkhead fittings and common PVC 2" pipe and fittings from the hardware or big box home improvement store. The only thing I had to order special was the bulkheads and buckets.

I will post a bill of materials with costs and sources along with a design diagram.

My plants have been in the system only a few weeks but are thriving and I can't believe the quality of the root system already. I have large root bundles as well as huge (pinky size) diameter main roots. The stems on my plants are bigger in diameter already compared to where my last grow finished.

All in all I am very happy with the system. Will be adding more detail shortly along with some photos.