TrichromeFan

- 1,850

- 83

OK guys,

I wanted to get a muffler to quiet my Vortex 6" fan down, and the local hydro shop had some unit for over $120, and it was stuffed with fiberglass! I sure as shit don't want to be breathing that being blown around by a fan, not to even mention for a scrubber application. So, I decided to make my own. Here goes...

Parts:

1 4' Concrete form cardboard tube

1 4' long roll of mesh screen called "harware cloth"

Some wood for making rings. I used 3/4 MDF

2 32 oz bags of polyester fiber fill

Misc:

zip ties

foil tape

silicone sealant

staples

Tools:

jigsaw (table saw and router would be a bonus)

stapler

hammer

cutter for zip ties

silicone gun

drill w/ drill bits

OK,

1:

Make some wood rings that fit inside my tube. I went with a 10" round tube (They make 8" & 12" tube sizes as well). I made 2 round pieces that fit the inside of the cardboard tubes. I made them just slightly loose, so I can slide them in and out easily. Then I made a hole in the center that would fit my duct size. In this case 6" around. I used a router, but you can just drill a pilot hole and use a jigsaw.

2:

Cut about 3" off the end of the cardboard tube. I used a table saw, but a jigsaw would work fine. That way, the end of the 4' screen will stick out enough for me to make a flange to attach my ducting to.

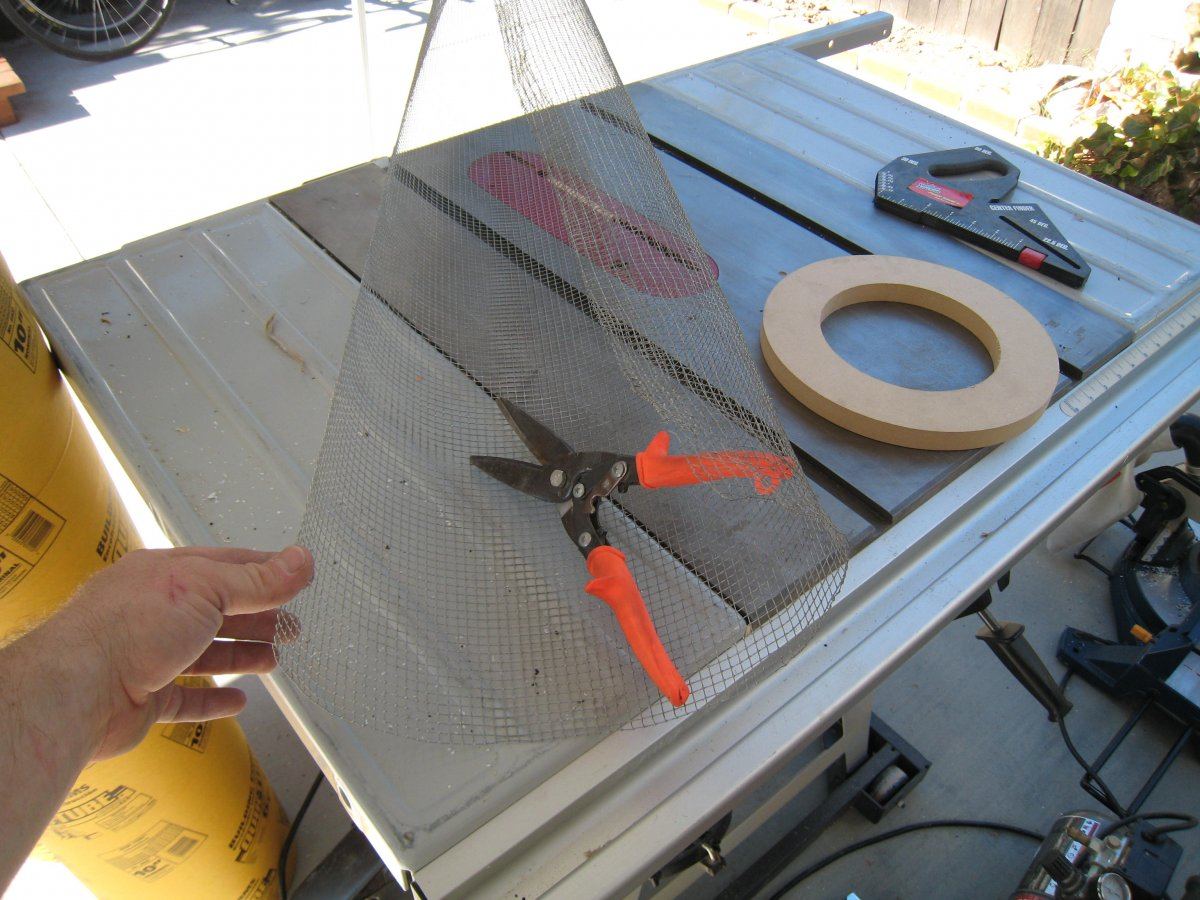

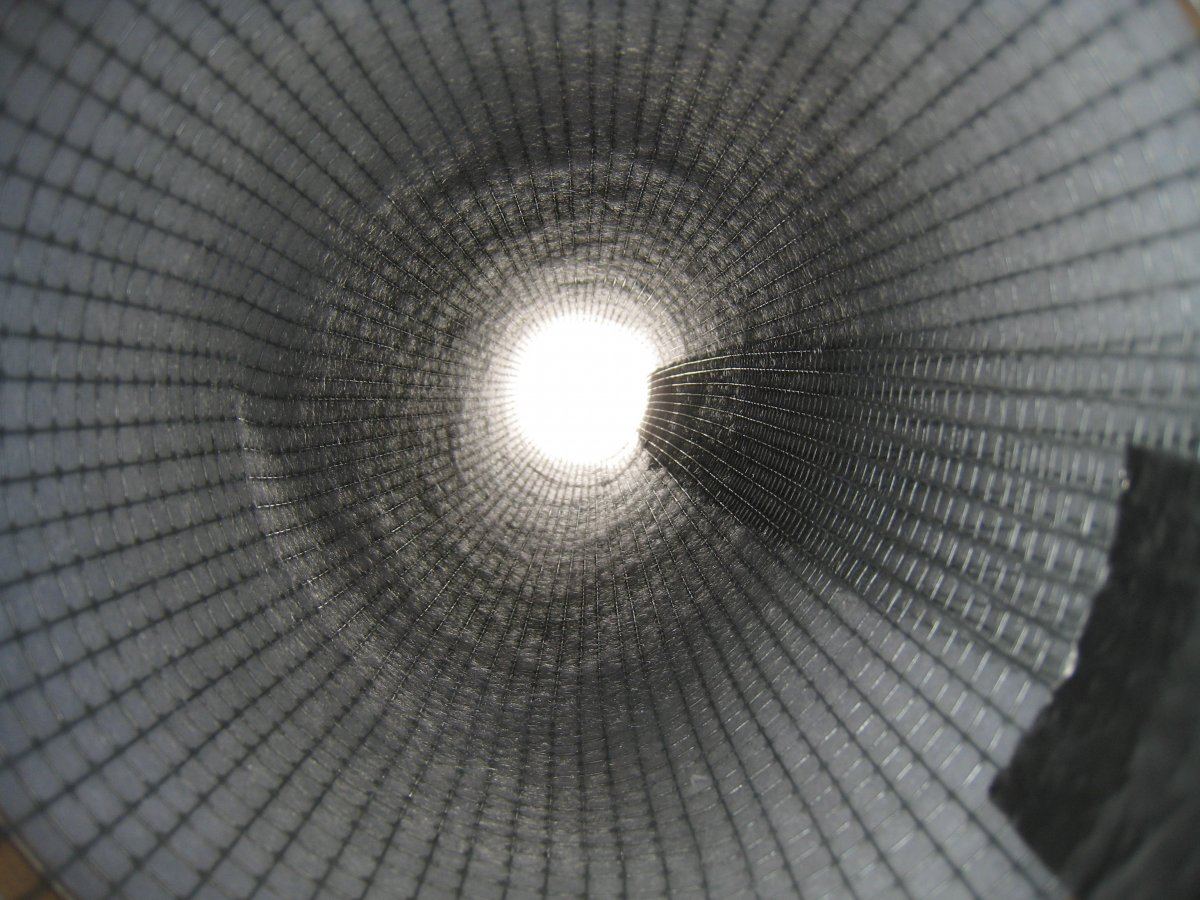

3:

Cut the screen lengthwise. Mine was about 20" wide. I rolled it into a tube, and placed it into the rings that I made.

4:

Stapled the screen inside the end ring on that is not a flange. I tried to get the staples all the way around, almost touching. Tap gently with the hammer if they need to go in further, or to smooth out the screen. Then I slid it into the tube to align the top ring, so it could be stapled as well.

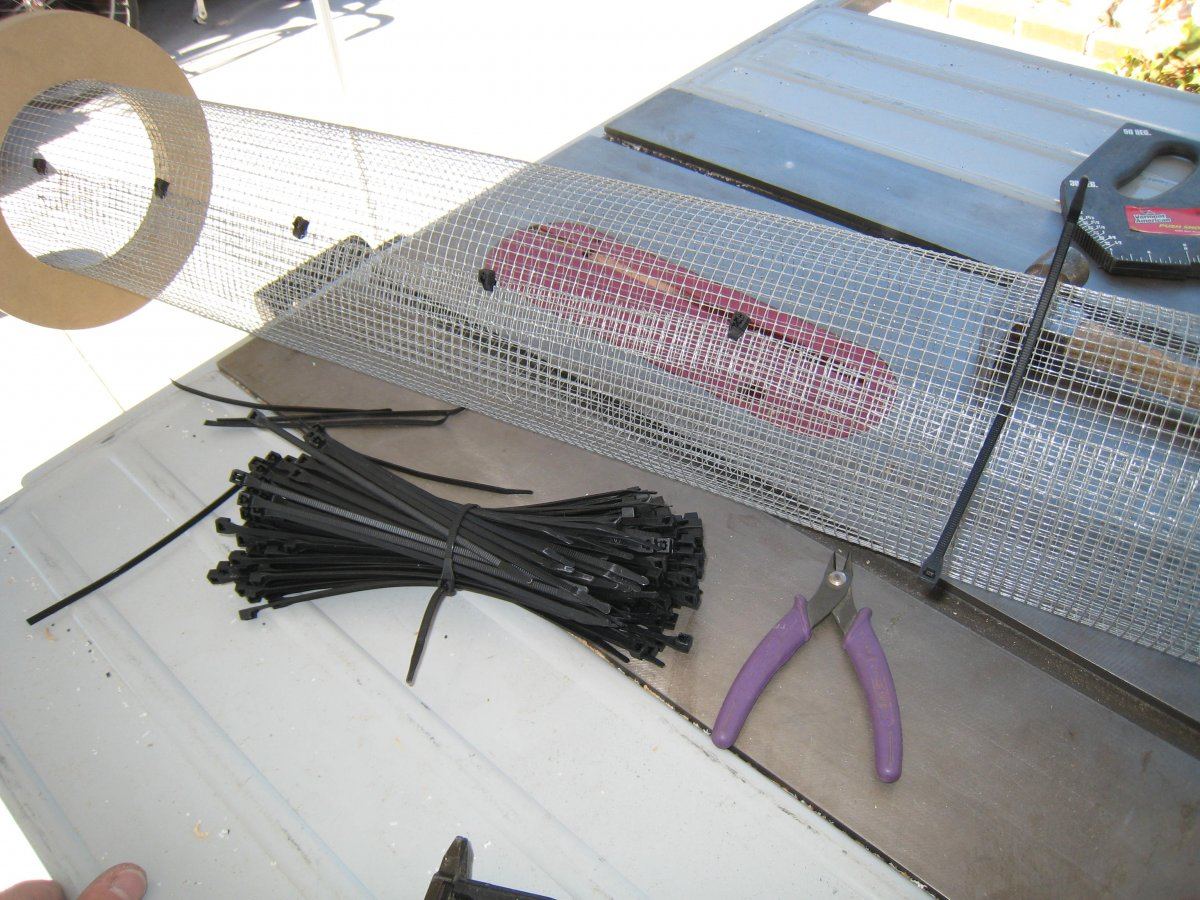

5:

Zip tied the flaps together about every 6" or so. That way it keeps a nice round shape. One at the end of the flange for good measure.

6:

Slide the screen into the tube a little, and slowly started stuffing in poly fill around the outside of the screen tube. Pay attention that it is pretty firmly packed, and that it is evenly packed around all sides. If not, it will want to shift to one side. Work your way down till you get the whole thing in. Then push the other end out, and back fill till it is stuffed well. I had to use a little spatula to get the last bits to go in cleanly. Total poly fill used was only 1.5 bags.

7:

Staple the tubes around the outside, into the wood rings.

8:

Use the foil tape to wrap the end of the screen that sticks out, to make a flange. Run a small bead of silicone around where the wood meets the flange, and on the outside edges.

Done! Ready to quiet down some noisy fans!

You could make just about any size with this stuff as well.

Coming part 2:

a little spiffy finish work, and installation...

-TF:evilgrin0013:

I wanted to get a muffler to quiet my Vortex 6" fan down, and the local hydro shop had some unit for over $120, and it was stuffed with fiberglass! I sure as shit don't want to be breathing that being blown around by a fan, not to even mention for a scrubber application. So, I decided to make my own. Here goes...

Parts:

1 4' Concrete form cardboard tube

1 4' long roll of mesh screen called "harware cloth"

Some wood for making rings. I used 3/4 MDF

2 32 oz bags of polyester fiber fill

Misc:

zip ties

foil tape

silicone sealant

staples

Tools:

jigsaw (table saw and router would be a bonus)

stapler

hammer

cutter for zip ties

silicone gun

drill w/ drill bits

OK,

1:

Make some wood rings that fit inside my tube. I went with a 10" round tube (They make 8" & 12" tube sizes as well). I made 2 round pieces that fit the inside of the cardboard tubes. I made them just slightly loose, so I can slide them in and out easily. Then I made a hole in the center that would fit my duct size. In this case 6" around. I used a router, but you can just drill a pilot hole and use a jigsaw.

2:

Cut about 3" off the end of the cardboard tube. I used a table saw, but a jigsaw would work fine. That way, the end of the 4' screen will stick out enough for me to make a flange to attach my ducting to.

3:

Cut the screen lengthwise. Mine was about 20" wide. I rolled it into a tube, and placed it into the rings that I made.

4:

Stapled the screen inside the end ring on that is not a flange. I tried to get the staples all the way around, almost touching. Tap gently with the hammer if they need to go in further, or to smooth out the screen. Then I slid it into the tube to align the top ring, so it could be stapled as well.

5:

Zip tied the flaps together about every 6" or so. That way it keeps a nice round shape. One at the end of the flange for good measure.

6:

Slide the screen into the tube a little, and slowly started stuffing in poly fill around the outside of the screen tube. Pay attention that it is pretty firmly packed, and that it is evenly packed around all sides. If not, it will want to shift to one side. Work your way down till you get the whole thing in. Then push the other end out, and back fill till it is stuffed well. I had to use a little spatula to get the last bits to go in cleanly. Total poly fill used was only 1.5 bags.

7:

Staple the tubes around the outside, into the wood rings.

8:

Use the foil tape to wrap the end of the screen that sticks out, to make a flange. Run a small bead of silicone around where the wood meets the flange, and on the outside edges.

Done! Ready to quiet down some noisy fans!

You could make just about any size with this stuff as well.

Coming part 2:

a little spiffy finish work, and installation...

-TF:evilgrin0013: