mrfixit

- 81

- 33

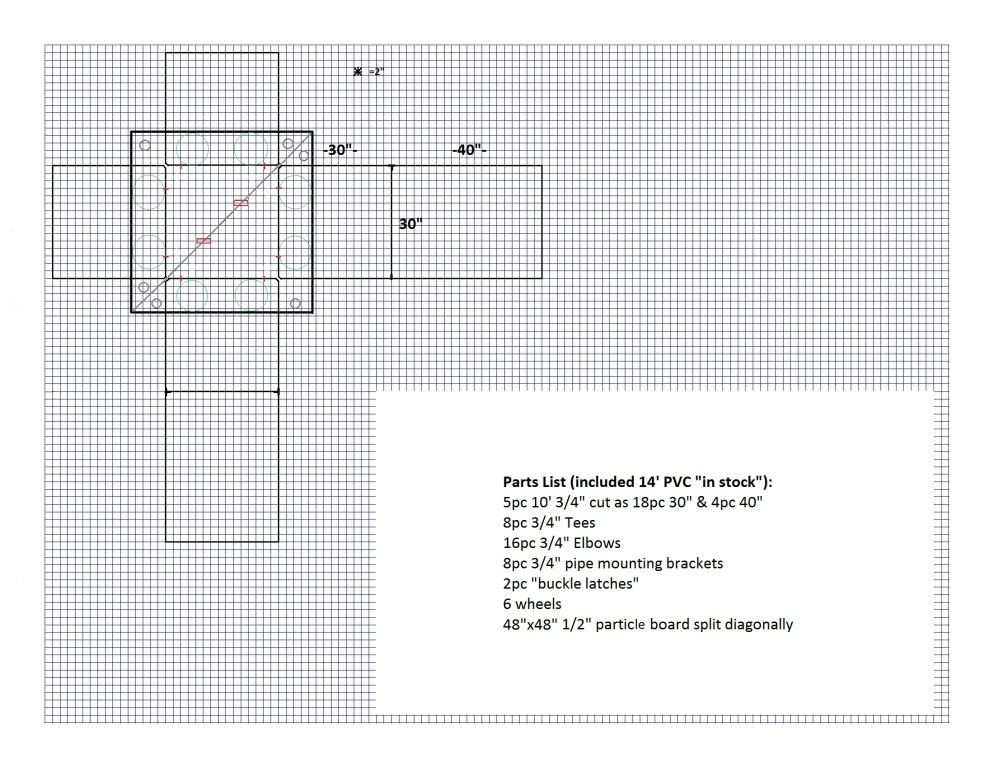

So this is my updated version of my "V" VSCRoG. The original "V" 2 sided version works well (look up my other posts) but had an inherent issue relative to a continuous grow cycle. This version separates into "halves" and can be cycled between veg and bloom, as well as it allows extension panels for the second half of growth.

Used 3/4" PVC, drywall screws instead of pricy eye hooks etc, and was able to keep costs down to a minimum. This version is 4'x4' but could easily be scaled up or down in size depending on your space or needs. And it's on wheels that will support/allow movement as a unit or in either half, making it easy to move a section out of veg into bloom. This one is scaled to have a fair amount of room for 2 5g smart pots on each side.

It is also ideal for vertical lighting (how I'll use it) but can work well with top and/or side lights also. I'll have a 1k HPS dropped down the center, a 400wMH for some extra canopy hardening and could also use tube florescent/mongo CFL or even LED for inside or backside lighting. It can be a straight sided "box" or the panels can be tilted individually to any angle and then held by either side chains between the panels or via to chains to the ceiling.

Used 3/4" PVC, drywall screws instead of pricy eye hooks etc, and was able to keep costs down to a minimum. This version is 4'x4' but could easily be scaled up or down in size depending on your space or needs. And it's on wheels that will support/allow movement as a unit or in either half, making it easy to move a section out of veg into bloom. This one is scaled to have a fair amount of room for 2 5g smart pots on each side.

It is also ideal for vertical lighting (how I'll use it) but can work well with top and/or side lights also. I'll have a 1k HPS dropped down the center, a 400wMH for some extra canopy hardening and could also use tube florescent/mongo CFL or even LED for inside or backside lighting. It can be a straight sided "box" or the panels can be tilted individually to any angle and then held by either side chains between the panels or via to chains to the ceiling.