D

dirtbag916

- 5

- 3

I am hoping that enough people will respond, or at least ones with the proper experience and know-ho to provide the answers that I am seeking. I have seen various plans for building vacuum purging systems and most seem to use relatively the same method (at least the ones that are more professional), however certain aspects have been very unclear especially as I have very little experience constructing pressurized systems.

Currently I have a 9 qt aluminum pressure cooker pot for the vat, a 3cfm two-stage vacuum pump with both R134A and R12/R22 fittings. Most guides say "oh you can find all the lines at home depot, or even a autoparts store". Home depots in my area have VERY poor selection of lines, especially since they will be under pressure and exposed to butane which I know can be corrosive so I don't want flimsy crap lines, not to mention they do not have any kind of fitting matching R134A or R12/R22 connectors. (is that just another term for FLARE fittings?) The only place I was able to even find a line that would suffice was from an auto parts warehouse and I found 2 AC/Refrigeration recharging hoses (sufficient?). The package states that it has a 1/4" female R134A flare on each side, I just wondered why both sides do not look exactly the same (refer to first picture, see that little metal dot inside one and not the other?)

I am attempting to get my hands on a clear polycarbonate or acrylic sheet, at least 1" thick but most plastic supply stores around me dont have them that thick and the few that do will cut to size for somewhere around 80$ or more. (buy online? any price-conscious recommendations on sites?) I've seen numerous plans where the lines are attached directly through the clear lid but never stated HOW that is done. I am guessing drilling a hole into the plastic and then using a threaded tap to add threads and then inserting a close nipple with a gasket to seal the connection, maybe even using some polymer or epoxy at the point of connection, but I am not sure. I have seen plans where a hole was made into the wall of the aluminum chamber itself and then used a brass bulkhead fitting with a washer and gasket to secure a port, which was then connected to a cross, but I have been unable to find any sort of bulkhead fitting that was small enough and not made of PLASTIC. Not to mention that finding a 1/4" (or any size for that matter) NPT to 1/4" R134A conversion piece is just about impossible at all hardware stores that I have checked, I am going to attempt to check HVAC and refrigeration supply stores tomorrow once they are open. (suggestions?)

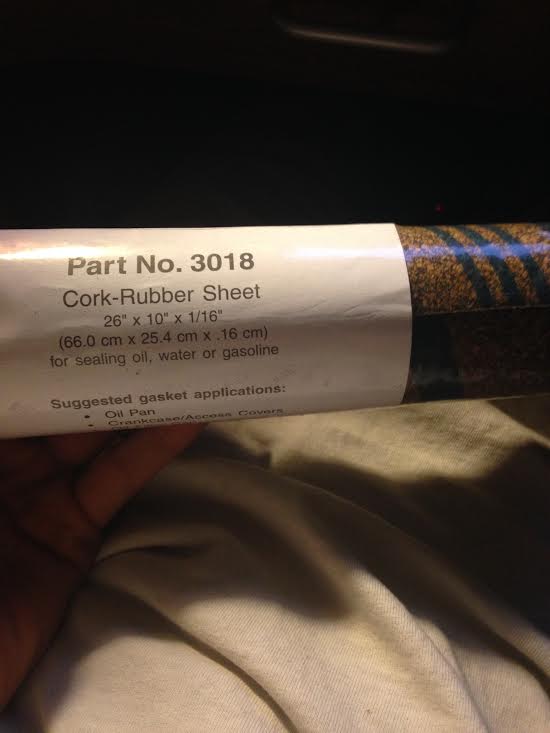

Last and least of my questions, the material I found for constructing a gasket around the mouth of the pot to seal to the lid is made of cork-rubber and im unsure if this is going to stand up to the temperatures that the pot is going to be exposed to.

Any information would be greatly helpful such as: whats the easier/safer/whatever way of attaching your vacuum lines to the actually degassing chamber (through plastic lid or chamber wall? One at a time or to a cross/tee connector) and what to use when attaching, also any information on why I am having such a terribly hard time finding the right fittings and adapters (is my only hope to just order online?) Also if I have any terrible flaws in my design.

If I could just know of a connector that would attach to my vacuum hoses that i could just SHOVE right into the polycarbonate (after threading it?) or even shoving it and then gluing using epoxy or polymer, it would save the hastle of finding these hard-to-locate adapter pieces. Also when making the connections I am assuming i need to be using gaskets of some kind but should i use something like loctite or a silicone glue when connecting the fittings so they stay airtight in a pressurized system?

Thankfully im not a total noob when it comes to actually blasting and purging to get desired quality of concentrates but when it comes to a pressurized system I am as noob as they come so any help is greatly appreciated. Thanks tokers

Currently I have a 9 qt aluminum pressure cooker pot for the vat, a 3cfm two-stage vacuum pump with both R134A and R12/R22 fittings. Most guides say "oh you can find all the lines at home depot, or even a autoparts store". Home depots in my area have VERY poor selection of lines, especially since they will be under pressure and exposed to butane which I know can be corrosive so I don't want flimsy crap lines, not to mention they do not have any kind of fitting matching R134A or R12/R22 connectors. (is that just another term for FLARE fittings?) The only place I was able to even find a line that would suffice was from an auto parts warehouse and I found 2 AC/Refrigeration recharging hoses (sufficient?). The package states that it has a 1/4" female R134A flare on each side, I just wondered why both sides do not look exactly the same (refer to first picture, see that little metal dot inside one and not the other?)

I am attempting to get my hands on a clear polycarbonate or acrylic sheet, at least 1" thick but most plastic supply stores around me dont have them that thick and the few that do will cut to size for somewhere around 80$ or more. (buy online? any price-conscious recommendations on sites?) I've seen numerous plans where the lines are attached directly through the clear lid but never stated HOW that is done. I am guessing drilling a hole into the plastic and then using a threaded tap to add threads and then inserting a close nipple with a gasket to seal the connection, maybe even using some polymer or epoxy at the point of connection, but I am not sure. I have seen plans where a hole was made into the wall of the aluminum chamber itself and then used a brass bulkhead fitting with a washer and gasket to secure a port, which was then connected to a cross, but I have been unable to find any sort of bulkhead fitting that was small enough and not made of PLASTIC. Not to mention that finding a 1/4" (or any size for that matter) NPT to 1/4" R134A conversion piece is just about impossible at all hardware stores that I have checked, I am going to attempt to check HVAC and refrigeration supply stores tomorrow once they are open. (suggestions?)

Last and least of my questions, the material I found for constructing a gasket around the mouth of the pot to seal to the lid is made of cork-rubber and im unsure if this is going to stand up to the temperatures that the pot is going to be exposed to.

Any information would be greatly helpful such as: whats the easier/safer/whatever way of attaching your vacuum lines to the actually degassing chamber (through plastic lid or chamber wall? One at a time or to a cross/tee connector) and what to use when attaching, also any information on why I am having such a terribly hard time finding the right fittings and adapters (is my only hope to just order online?) Also if I have any terrible flaws in my design.

If I could just know of a connector that would attach to my vacuum hoses that i could just SHOVE right into the polycarbonate (after threading it?) or even shoving it and then gluing using epoxy or polymer, it would save the hastle of finding these hard-to-locate adapter pieces. Also when making the connections I am assuming i need to be using gaskets of some kind but should i use something like loctite or a silicone glue when connecting the fittings so they stay airtight in a pressurized system?

Thankfully im not a total noob when it comes to actually blasting and purging to get desired quality of concentrates but when it comes to a pressurized system I am as noob as they come so any help is greatly appreciated. Thanks tokers