Curious.......you say that fan performance is degraded because of filter restriction on the frontside(input air) causing improper fan load. Most modern a/c's use a filter front design which would be in conflict to what you are saying would optimize fan performance. Is the difference the filter media that is being used in relation to the fan CFM being employed on that particular design? In another thread front side filtering was mentioned as a way to keep fan components cleaner. True or not?

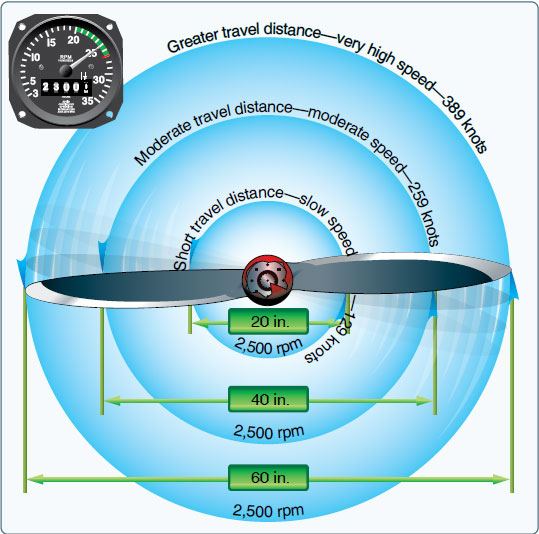

Also, you say that with the input side unloaded, other than tent vents, the fan can load properly but you also say that pressure drop is the same be it suction or discharge with the same filter on either end. I'm assuming your increase in fan performance is what is yielding you the better discharge numbers. In essence the higher flow rates will flow more out of the filter. What I don't get is if the filter media has a flow limit how can the increased performance of the fan surpass that limit? Are you saying that the lower performance of , say an ACI T6 unit since you mentioned ACI fans, doesn't push the filter to its limit thus lowering net cfm? Because the filter is not being pushed to its CFM limits would the fan performance not match whatever level the filter is allowing it to flow on the frontside/input side of the fan vs being used on the discharge side? I'm sure there are some physics and aero laws that would explain this but I'm curious about your explanation and how that works.

BTW did you rinse your filters before hooking them up to mitigate carbon dust? I know you used the prefilter inside the chamber but putting it on the outside, IMO, would be better to keep carbon dust from escaping into the atmosphere. Prefilter on the inside or outside should have no difference in relation to airflow but I could be wrong.

ALSO, LOL, since we're on the subject of airflow, when in flower, to keep the girls in total darkness I have to cover my vent panels. I have two 6" vents that I plan on using as my input air but I need to connect a length of flex duct to kill whatever light is entering. I tested the airflow, no instrument testing just SOP testing by how much negative pressure the tent was under through visual. How do I calculate how much vent area I need to properly supply the tent and fan? I have an ACI T6 unit in the vent and am thinking of using your setup of filter on the discharge end.