Ganjalf

- 4

- 3

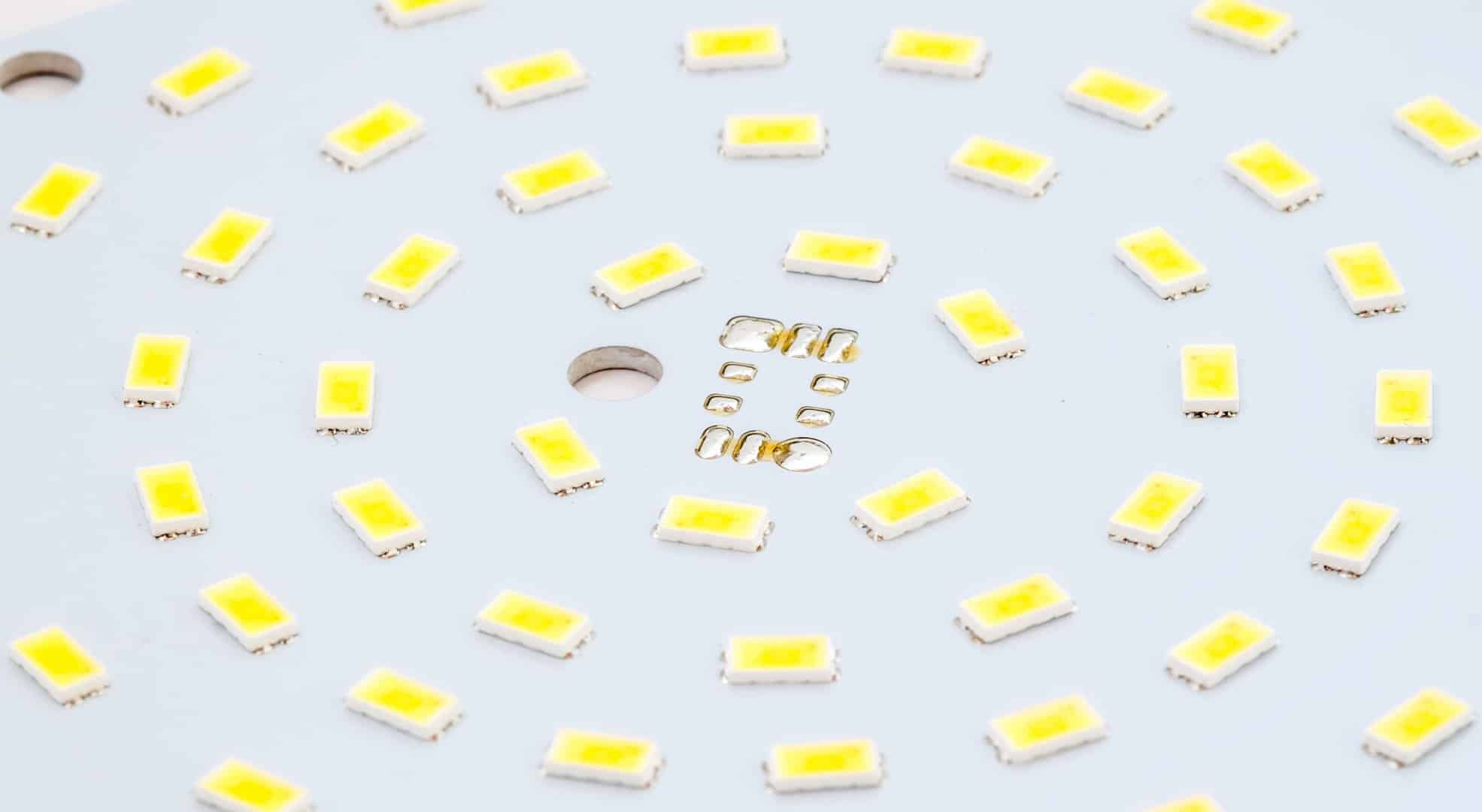

Hi there guys I am considering creating my own LED light to substitute the one I have, I am a microgrower, it would be for a space of 0.5x0.5 m2.

I thought of 272 Samsung LM301B, 6 deep red Osram OSCONIQ P 3030 and a 200W Mean Well or Inventronics Driver, my question comes regarding the PCB. My idea was to create an aluminum structure to dissipate heat and use 4 PCB strips of 380x30 mm where to put two rows of LEDs, but I don't know whether there are better options or if I have to use a Metalcore PCB, a regular PCB or a starboard. Could anybody point me in the right direction?

I thought of 272 Samsung LM301B, 6 deep red Osram OSCONIQ P 3030 and a 200W Mean Well or Inventronics Driver, my question comes regarding the PCB. My idea was to create an aluminum structure to dissipate heat and use 4 PCB strips of 380x30 mm where to put two rows of LEDs, but I don't know whether there are better options or if I have to use a Metalcore PCB, a regular PCB or a starboard. Could anybody point me in the right direction?