OB1Ganjobi

- 49

- 18

Hey All

I live out here in Beautiful Colorado and recently we purchased a closed loop extraction system from some real chill guys at LOOP BOTANICALS! They came out and showed me the ins and outs of the system and how it all works. This system was the only one that has a HUGE glass window in the catch chamber so you can watch your extraction happen. I’ve been very pleased with the ease of the system, its fast, simple and makes me wonder how much time and butane I’ve wasted in the past, and considering the price difference between this one and other systems of the same size I’ve already saved thousands on the system and hundreds on butane.

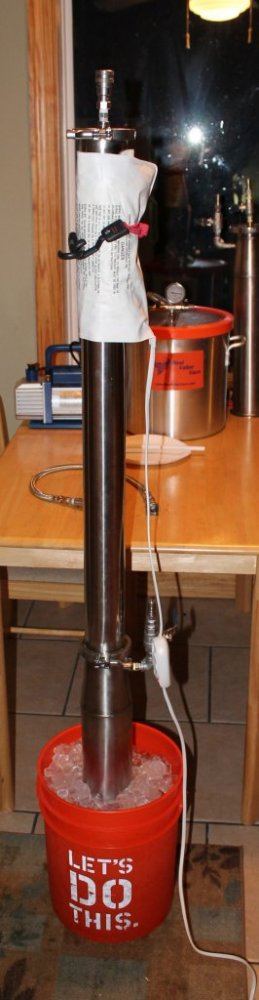

This is the pic of the system from their Facebook page. Check em out!

Here’s the system ready to put together. I have all Grape Ape indoor trim, small buds and lots of nice greenhouse nugs packed in there. All together about 1.25lbs of material.

The tank goes in a 5 gal. bucket of ice and water until its at or below freezing and the butane bottles are kept on a heat pad in order to keep them a little warmer than room temp. A full case of butane fits into the Storage Tank and it goes in by manually opening and closing the quick connect valve as its blasted into the tank.

The Butane Storage Tank is weighed empty and full so we know when all the butane has been blasted into and through the Trim Chamber.

The system assembled and ready to go.

In Laman’s Terms…

Butane in liquid form is cold and naturally wants to go to the coldest chamber it can get to. So, we’re making the butane go from its Storage Tank, through the Trim Chamber, into our Catch Chamber, then back to its Storage Tank using a heating pad, ice water and boiling water leaving only BHO behind.

The Storage Tank has a heat pad wrapped around it to force the butane out of the Storage Tank, through the Trim Chamber and into the Catch Chamber that is sitting in a bucket of ice and water. The butane naturally wants to go to the colder chamber and is taking all the goodness with it!

View attachment 381651

Once the Storage Tank has been weighed to make sure all the butane is in the Trim Chamber and going into the Catch Chamber, its taken off the Trim Chamber and the heat pad is moved to the top of the Trim Chabmer to force the all butane down to the Catch Chamber.

This system is AWESOME!!! Its pretty sweet to watch the Catch Chamber fill with golden liquid.

Once the Trim Chamber has been warmed from the heat pad being slowly moved to the bottom of the Trim Chamber, all the butane is now in the Catch Chamber and its time to recycle the butane back in its Storage Tank.

The Storage Tank is placed in ice and water and the Catch Chamber is put in a 5 gal. bucket and filled with boiling water and kept hot by topping it off with fresh hot water to force the butane back in to its Storage Tank to be used again.

I’ve been getting about 75 to 80% return on butane.

As the butane is forced back to the Storage Tank you can watch through the glass and see all the bubbles of butane rising up and leaving the Catch Chamber.

Once the Catch Chamber is almost empty (@ 1/2 in. of BHO liquid) we take the system outside to slowly let off the excess gas until there’s pretty much no hissing (pressure) sound coming out of the Catch Chamber.

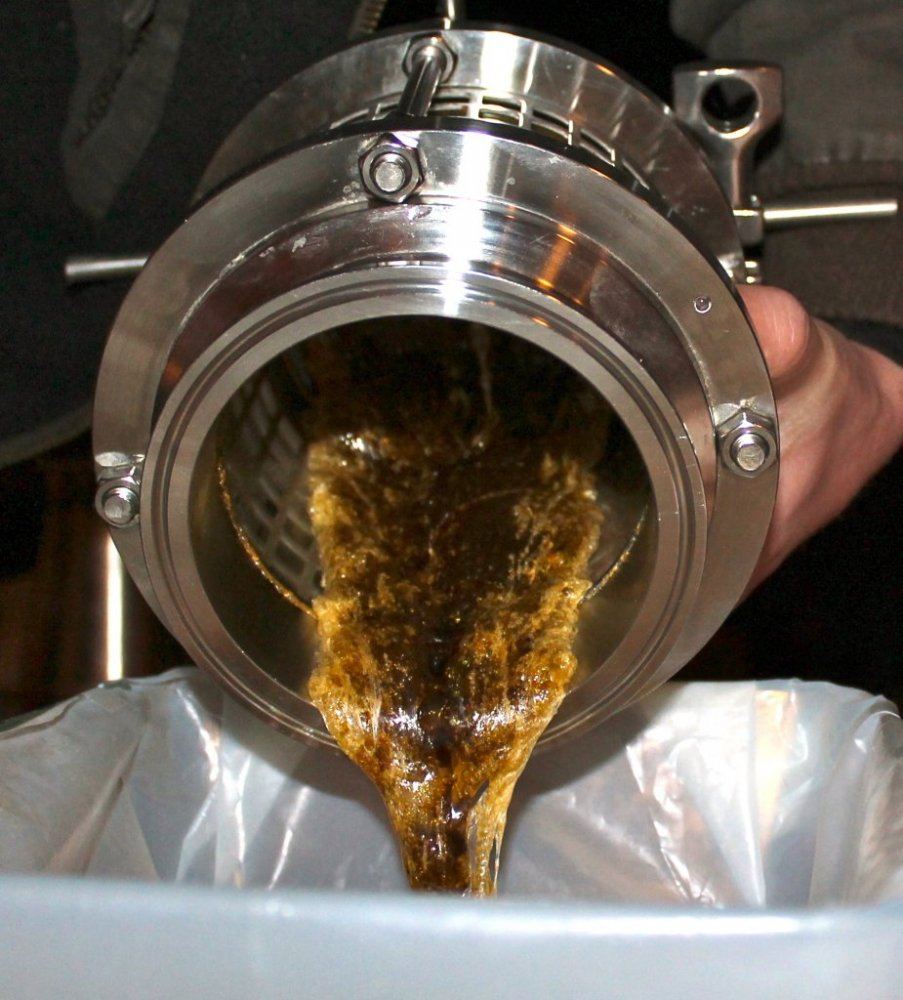

The Catch Chamber is opened and emptied into a glass dish lined with ‘Oil Slick – Slick Sheet’.

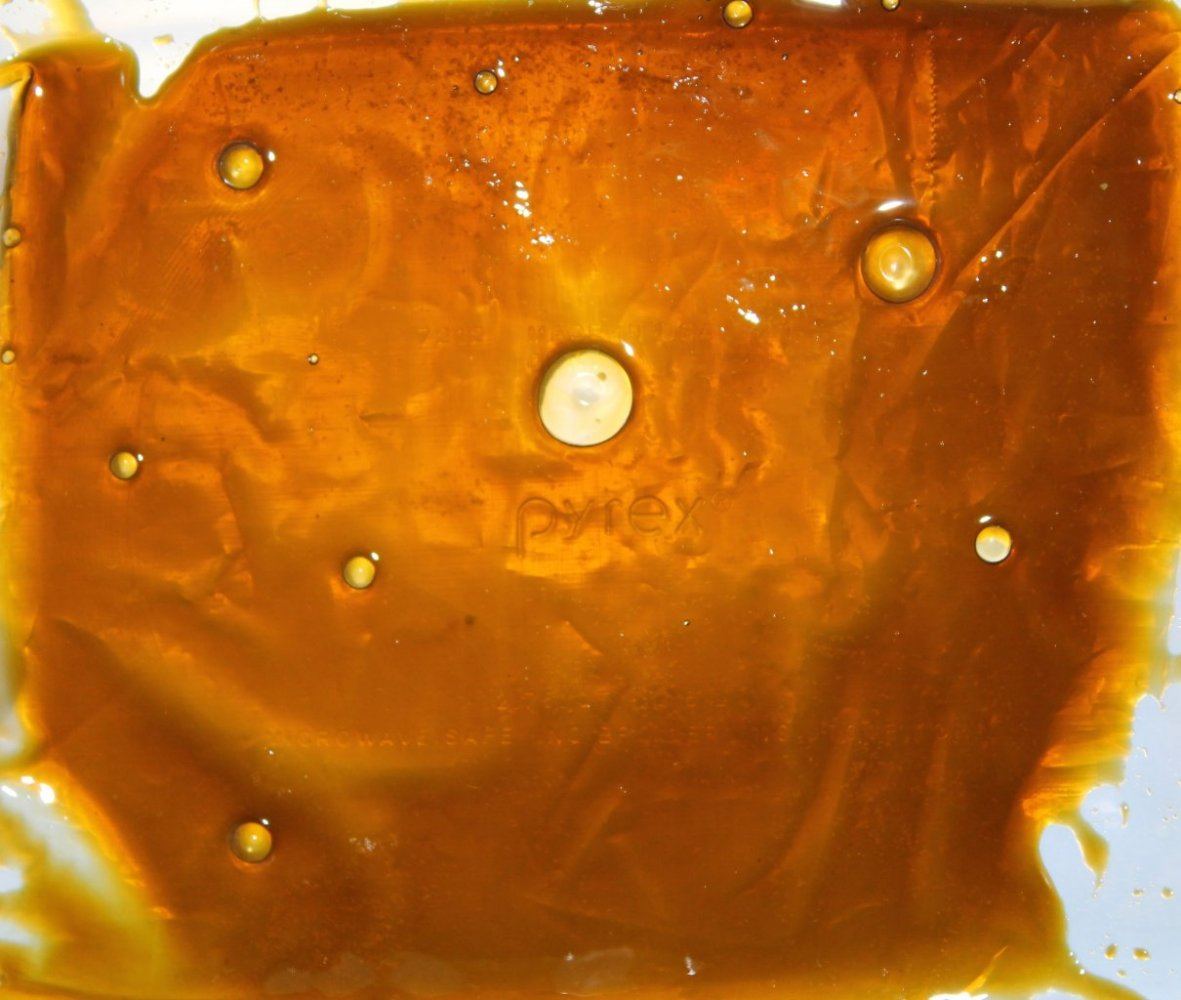

And now its time to put the BHO into a Heated Vac. Chamber and purge all the butane OUT and make it into some nice shatter and or honeycomb waxy goodness. It’s in at full vac. for about 12 hours at 120 degrees.

Looks like gold cotton candy as it puffs up during vac.

After its overnight purge it turned into an almost shatter but upon inspection with my loop I saw a few little bubbles so I put it back in the Vac. Chamber.

This time there was a lot of excess BHO left in the Catch Chamber that we scrapped out and put on parchment paper. While the majority is purging in the Vac. Chamber the rest of the excess is heated up with a CLEAN hair dryer and stirred like you would in a hot water bath. Then the parchment is folded in half, folding the BHO into itself to further purge. The excess was then left out overnight waiting for the heated Vac. Chamber.

The excess BHO goes into the heated Vac. Chamber to purge the last of the butane out and it turned into a honeycomb wax.

I live out here in Beautiful Colorado and recently we purchased a closed loop extraction system from some real chill guys at LOOP BOTANICALS! They came out and showed me the ins and outs of the system and how it all works. This system was the only one that has a HUGE glass window in the catch chamber so you can watch your extraction happen. I’ve been very pleased with the ease of the system, its fast, simple and makes me wonder how much time and butane I’ve wasted in the past, and considering the price difference between this one and other systems of the same size I’ve already saved thousands on the system and hundreds on butane.

This is the pic of the system from their Facebook page. Check em out!

Here’s the system ready to put together. I have all Grape Ape indoor trim, small buds and lots of nice greenhouse nugs packed in there. All together about 1.25lbs of material.

The tank goes in a 5 gal. bucket of ice and water until its at or below freezing and the butane bottles are kept on a heat pad in order to keep them a little warmer than room temp. A full case of butane fits into the Storage Tank and it goes in by manually opening and closing the quick connect valve as its blasted into the tank.

The Butane Storage Tank is weighed empty and full so we know when all the butane has been blasted into and through the Trim Chamber.

The system assembled and ready to go.

In Laman’s Terms…

Butane in liquid form is cold and naturally wants to go to the coldest chamber it can get to. So, we’re making the butane go from its Storage Tank, through the Trim Chamber, into our Catch Chamber, then back to its Storage Tank using a heating pad, ice water and boiling water leaving only BHO behind.

The Storage Tank has a heat pad wrapped around it to force the butane out of the Storage Tank, through the Trim Chamber and into the Catch Chamber that is sitting in a bucket of ice and water. The butane naturally wants to go to the colder chamber and is taking all the goodness with it!

View attachment 381651

Once the Storage Tank has been weighed to make sure all the butane is in the Trim Chamber and going into the Catch Chamber, its taken off the Trim Chamber and the heat pad is moved to the top of the Trim Chabmer to force the all butane down to the Catch Chamber.

This system is AWESOME!!! Its pretty sweet to watch the Catch Chamber fill with golden liquid.

Once the Trim Chamber has been warmed from the heat pad being slowly moved to the bottom of the Trim Chamber, all the butane is now in the Catch Chamber and its time to recycle the butane back in its Storage Tank.

The Storage Tank is placed in ice and water and the Catch Chamber is put in a 5 gal. bucket and filled with boiling water and kept hot by topping it off with fresh hot water to force the butane back in to its Storage Tank to be used again.

I’ve been getting about 75 to 80% return on butane.

As the butane is forced back to the Storage Tank you can watch through the glass and see all the bubbles of butane rising up and leaving the Catch Chamber.

Once the Catch Chamber is almost empty (@ 1/2 in. of BHO liquid) we take the system outside to slowly let off the excess gas until there’s pretty much no hissing (pressure) sound coming out of the Catch Chamber.

The Catch Chamber is opened and emptied into a glass dish lined with ‘Oil Slick – Slick Sheet’.

And now its time to put the BHO into a Heated Vac. Chamber and purge all the butane OUT and make it into some nice shatter and or honeycomb waxy goodness. It’s in at full vac. for about 12 hours at 120 degrees.

Looks like gold cotton candy as it puffs up during vac.

After its overnight purge it turned into an almost shatter but upon inspection with my loop I saw a few little bubbles so I put it back in the Vac. Chamber.

This time there was a lot of excess BHO left in the Catch Chamber that we scrapped out and put on parchment paper. While the majority is purging in the Vac. Chamber the rest of the excess is heated up with a CLEAN hair dryer and stirred like you would in a hot water bath. Then the parchment is folded in half, folding the BHO into itself to further purge. The excess was then left out overnight waiting for the heated Vac. Chamber.

The excess BHO goes into the heated Vac. Chamber to purge the last of the butane out and it turned into a honeycomb wax.

Last edited: