Dr.Dutch

- 64

- 18

So, I don't really know how to start here right now.... I had already said to Moe in his Fogponic thread that I must start a log here weeks ago..

As an introduction:

Currently we are in week 5 (Exactly day 36 today). Plants do not look so nice, as the title already implies. That's why it took a little longer with the report, had to change a few things first.

two days ago

.. removed all sick leaves (and once again realized that my tent is missing doors in the back )

)

Now

Back story (brief):

On the mother plants I had already tested the same mixture, which now led to problems.

The aim was only to adjust the pH with citric acid. For this purpose, the addition of glucose was tested, since previous tests indicated that this keeps the pH with the citric acid stable longer (tests conducted in open tank with circulation pump).

Mother plants were watered with a nutrient solution that was more than 14 days old and the cubes of the clones were also watered with it afterwards, which did not lead to any problems.

In the water lines, however, this fluctuating pH, which occurred with this mixture, leads to problems I think. There is always some nutrient solution in the line, where the pH can not be adjusted.

In addition, the nutrient solution was also visually and from the smell in the reservoir not as in the test before. To put it simply, it looked and smelled like sh**..

To go back a little further: I'm currently testing (or try it^^) many things from manicbotanix.com.

Theoretically, many things probably make sense there, but some I would see in the meantime also skeptical or have not looked at them critically enough when reading and so far and thought too little.

(Who is new here and does not know manics at all should perhaps read in Moe's thread, there is already a bit of it and from me

https://www.thcfarmer.com/threads/fogponics-as-good-or-better-than-hydro.142273/post-2850580).

So, long story short: With the acid and the glucose I have definitely promoted any MOs that I probably do not want to have.

A week ago then cleaned pump and res, flushed lines and back 2 basics with the nutrient solution.

Thrown out (so you get an overview): Citric, salicylic and ascorbic acid, amino/peptide fertilizer and mono aminos, kelp additive, chitosan and glucose.

There are basically four test formulations running now:

Today the new solution in T9 was additionally made with magnesium citrate. First test whether citrates are compatible or whether I need other fertilizer to get my sulfur levels down.

@N1ghtL1ght you can have a look at the video here. For @Moe.Red possibly also quite interesting. It is about the sense of carbon fertilization.

Had already said about to the article by Ferandez that this could be different with C3 plants than with the corn to which he referred.

Quite interesting in depth as it also says something about the reduction of nitrate and SO4 in the plant and how that competes with CO2.

Confirms then also again some things from manics

I will now test here in any case piece by piece, how the aminos and other things behave exactly in the tank. The BioPak itself does not seem to cause any problems or does what it should.

www.youtube.com

www.youtube.com

And if anyone wants to see the last test result: The sh**y res^^

So, we have most of it together for now. And I can still edit .

I will now add Mg citrate to T6 and rinse a few pots with the pressure pump sprayer. Don't like a drain pH of around 7.

As an introduction:

- ~1400w LED (something DIY and thrown together, will be changed when there is enough money, someday. But does the job)

- 2x 270w Hydroca BlueLine420 (3 chan 3500k; 440/450nm; 630/660nm)

- 4x 50w SANlight

- 48x 13/13,5w CorePro

- 10x5 Homebox, 540m³ Filter, 270m³ exhaust fan (swiss made silent box with low pressure drop, i am wondering myself that this works^^)

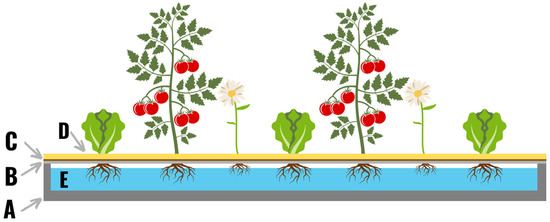

- Coco/Perlit (65/35) Hydro 3,5l containers (Canna Coco Professional)

- Serious Kush (Serious Seeds) 72 plants one genotyp. Third run with this genetic. One cannot speak of selection. 6 seeds, 3 germinated, one cripple and one discarded because of mold. But my mistake with the germination rate, I do not blame the breeder for this.

The SK#4 has stayed and is used at the moment for testing, result last time on Coco was very good with it. - DIY irrigation, Netafim, high pressure pump (Still not satisfied with the setup, details will follow)

- Fertilizers and additives only professionals and salts, calculation with excel (again details will follow)

Currently we are in week 5 (Exactly day 36 today). Plants do not look so nice, as the title already implies. That's why it took a little longer with the report, had to change a few things first.

two days ago

.. removed all sick leaves (and once again realized that my tent is missing doors in the back

Now

Back story (brief):

On the mother plants I had already tested the same mixture, which now led to problems.

The aim was only to adjust the pH with citric acid. For this purpose, the addition of glucose was tested, since previous tests indicated that this keeps the pH with the citric acid stable longer (tests conducted in open tank with circulation pump).

Mother plants were watered with a nutrient solution that was more than 14 days old and the cubes of the clones were also watered with it afterwards, which did not lead to any problems.

In the water lines, however, this fluctuating pH, which occurred with this mixture, leads to problems I think. There is always some nutrient solution in the line, where the pH can not be adjusted.

In addition, the nutrient solution was also visually and from the smell in the reservoir not as in the test before. To put it simply, it looked and smelled like sh**..

To go back a little further: I'm currently testing (or try it^^) many things from manicbotanix.com.

Theoretically, many things probably make sense there, but some I would see in the meantime also skeptical or have not looked at them critically enough when reading and so far and thought too little.

(Who is new here and does not know manics at all should perhaps read in Moe's thread, there is already a bit of it and from me

https://www.thcfarmer.com/threads/fogponics-as-good-or-better-than-hydro.142273/post-2850580).

So, long story short: With the acid and the glucose I have definitely promoted any MOs that I probably do not want to have.

A week ago then cleaned pump and res, flushed lines and back 2 basics with the nutrient solution.

Thrown out (so you get an overview): Citric, salicylic and ascorbic acid, amino/peptide fertilizer and mono aminos, kelp additive, chitosan and glucose.

There are basically four test formulations running now:

- Tank60 only with mineral nutrians, BioPak and BTI (tablet dissolved and filtered with coffee filter)

- Bucket with the same mixture as 1. without BTI.

These two to see how the MOs behave without other organics.

PH/EC has been stable here for seven days and both look great. - Tank90 BioPak, Tween20 ( Surfactant) und Fulvic twice.

- reservoir with the pump. Is currently filled from tank90(T9), after a week virtually no sediment and as clear as on the first day. BTI (as above) was also added here a few days ago, does not cause any problems with Fulvic, Tween20 and BioPak

Today the new solution in T9 was additionally made with magnesium citrate. First test whether citrates are compatible or whether I need other fertilizer to get my sulfur levels down.

@N1ghtL1ght you can have a look at the video here. For @Moe.Red possibly also quite interesting. It is about the sense of carbon fertilization.

Had already said about to the article by Ferandez that this could be different with C3 plants than with the corn to which he referred.

Quite interesting in depth as it also says something about the reduction of nitrate and SO4 in the plant and how that competes with CO2.

Confirms then also again some things from manics

I will now test here in any case piece by piece, how the aminos and other things behave exactly in the tank. The BioPak itself does not seem to cause any problems or does what it should.

Carbon Concentration and Metabolism in Cannabis Plants

Nik NikolayevRooted Leaf Agritechhttps://dagga.garden/product-category/garden/rooted-leaf/https://www.instagram.com/therootedleaf/Cannabis plants have tools ...

And if anyone wants to see the last test result: The sh**y res^^

So, we have most of it together for now. And I can still edit .

I will now add Mg citrate to T6 and rinse a few pots with the pressure pump sprayer. Don't like a drain pH of around 7.

Last edited: